Mechanical Seal Test Bench

National geographic recommended for you.

Mechanical seal test bench. This method used as a static leak test on large mechanical seals is usually unable to detect a leak as it is generally impossible to view the inside of the mechanical seal e g. Tests of the prototype seal were performed on a special purpose test bench fig. An average liquid leakage rate of less than 5 6 g h per pair of seal faces. A guide value for the detection sensitivity achieved by this method is 0 5 mbar 1 s.

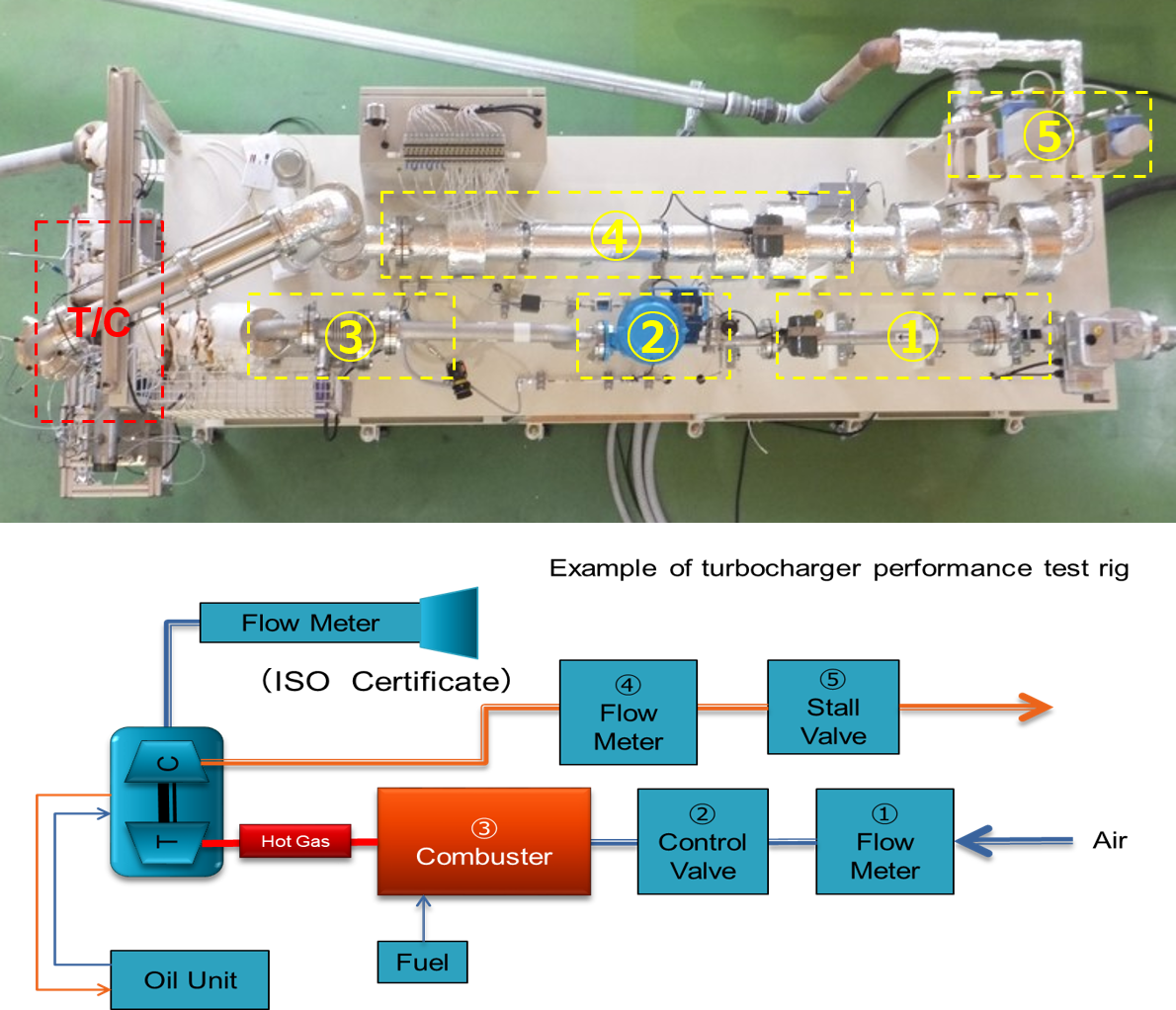

A variety of test procedures and mechanical test equipment exists in today s market. This involves connecting the complete seal to a tank of pressurised air then measuring the pressure drop over five minutes to assess the leakage. 2 process gas chamber. 109 year old veteran and his secrets to life will make you smile short film showcase duration.

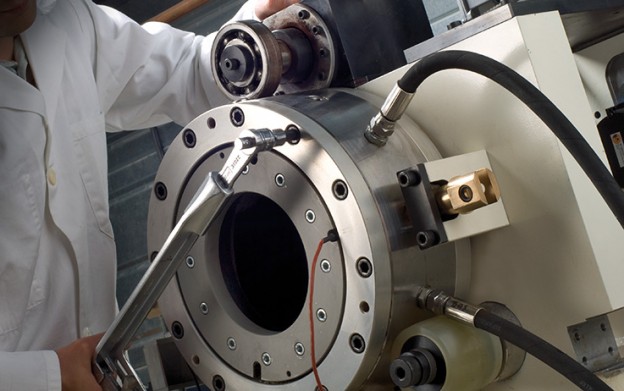

Testing determines the component s operational life expectancy. Its sliding faces in the assembled state. Mechanical seal air test at our facility. The rotational speed of the shaft or axel the pressure the temperature and the nature of the medium.

The cooling and lubricating liquid. Agitators are equipped with mechanical seals the test of a mechanical seal depends on its design and purpose. Api 682 iso 20149 section 10 3 1 4 1 additionally each assembled seal must be subjected to a quality assurance test. Scheme of the housing and a pneumatic and hydraulic system for the 30gsl a5 i 439 seal testing.

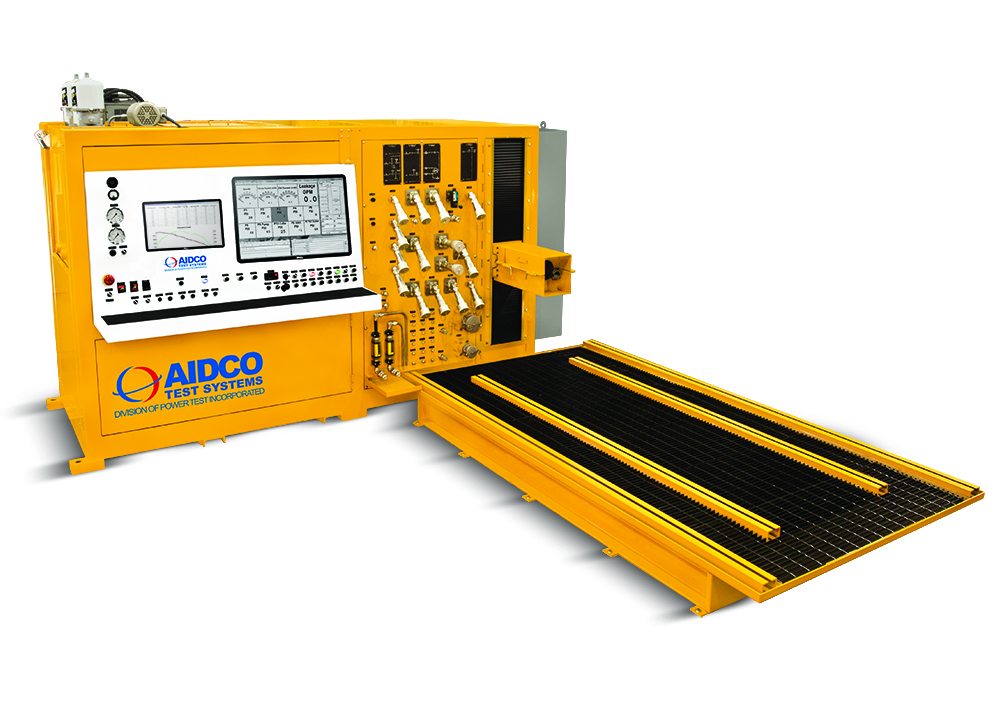

Mechanical test bench bpr fdt encsa test bench with three stations for traction and flexion tests on flexible hoses according to en 1113 and asme a112 18 1 2012 csa b125 1 12 standards. 1 tested seal. Shaft seal bench validation. The american petroleum institute standard for mechanical seals api 682 includes a test of the final cartridge assembly using pressurized air.

The purpose of this test is to prove that the cartridge has been assembled properly. Succession of individual tests implemented parameters and fig. However the test variously called the air test or integrity test is widely misunderstood. The invention discloses a contact high speed mechanical seal testing device which comprises a bench a main test chamber a high speed torque gauge coupler a drive motorized spindle and a cooling and lubricating liquid supply system wherein the main test chamber the high speed torque gauge coupler and the drive motorized spindle are mounted on the bench.