Metal Injection Molding Process Ppt

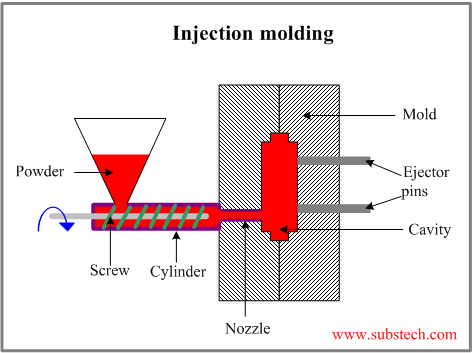

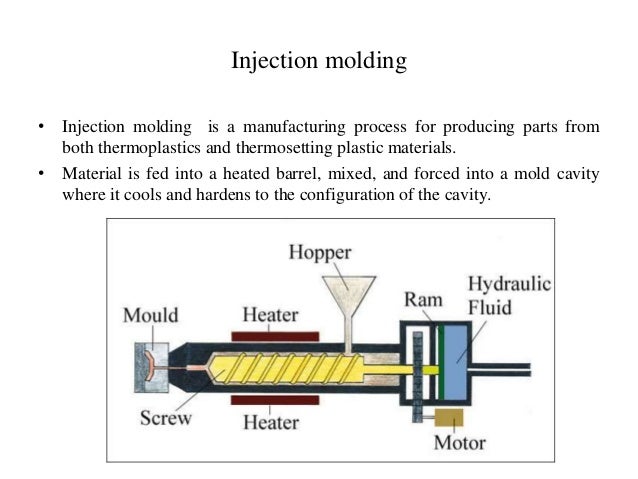

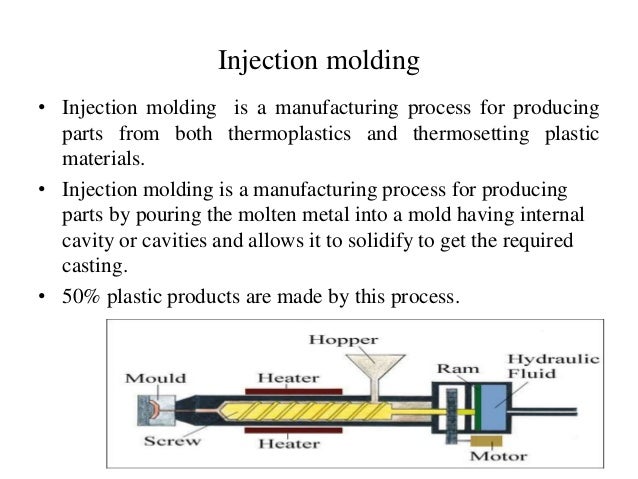

Injection molding is the most commonly used manufacturing process for the fabrication of plastic parts.

Metal injection molding process ppt. Polypropylene is used for table chair and rehl as raw material. Polypropylene is cheap has low melting point can be recycled. Rubber injection moulding 6. A wide variety of products are manufactured using injection molding which vary greatly in their size complexity and application.

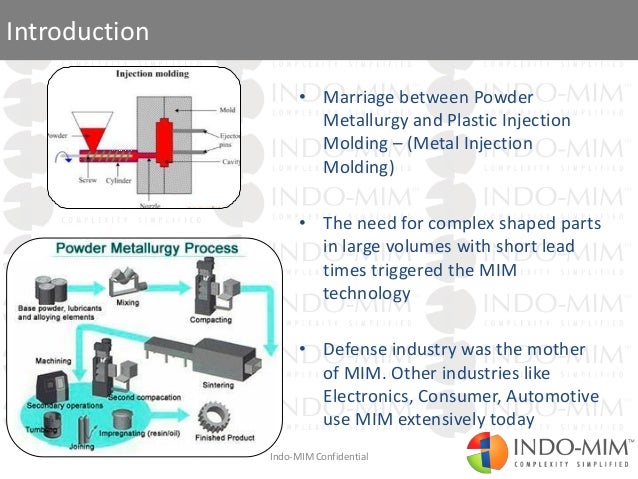

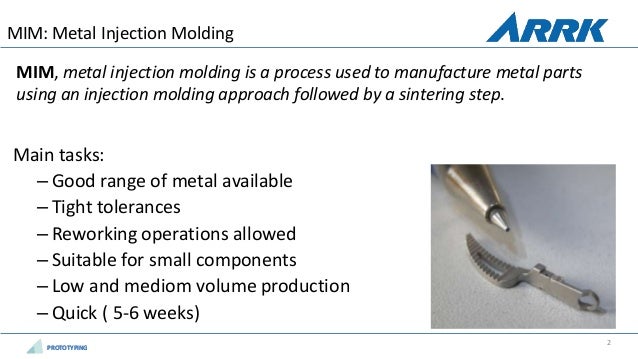

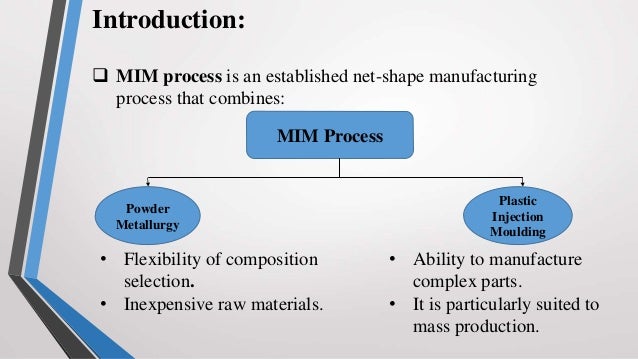

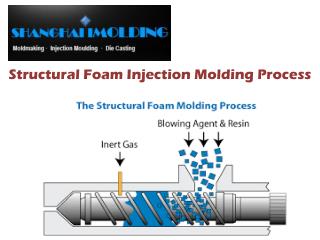

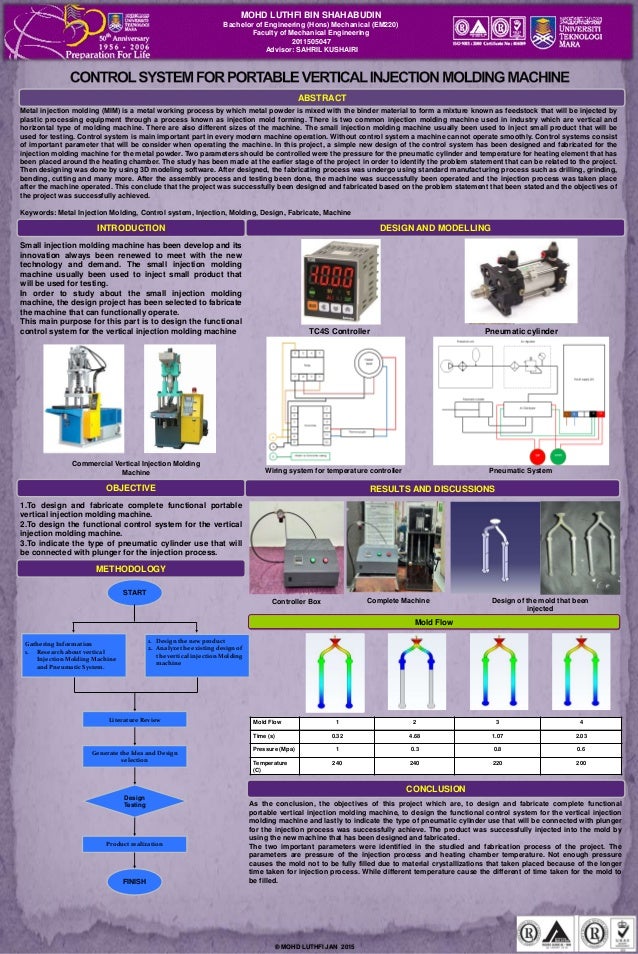

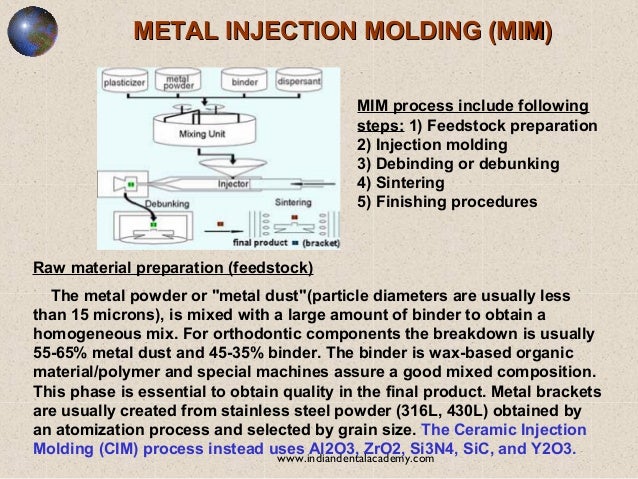

Metal injection moulding 1 metal injection moulding. The metal injection molding process is usually called by its short acronym mim as it will do in this work. Metal injection molding mim merges two established technologies plastic injection molding and powdered metallurgy. Fine metal powder less than 20µ particle size is blended with thermoplastic and wax binders in precise amounts.

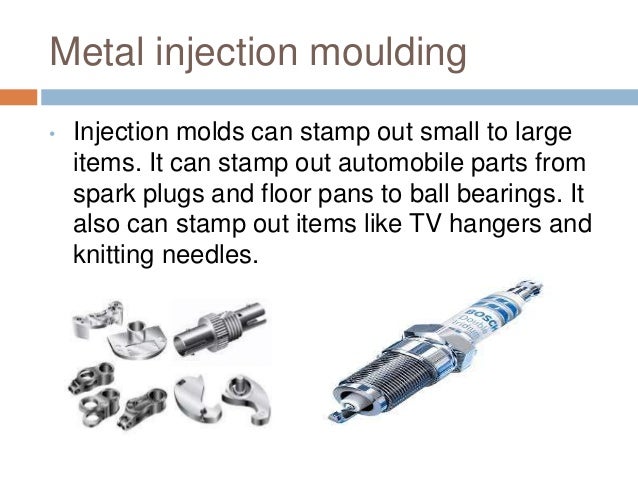

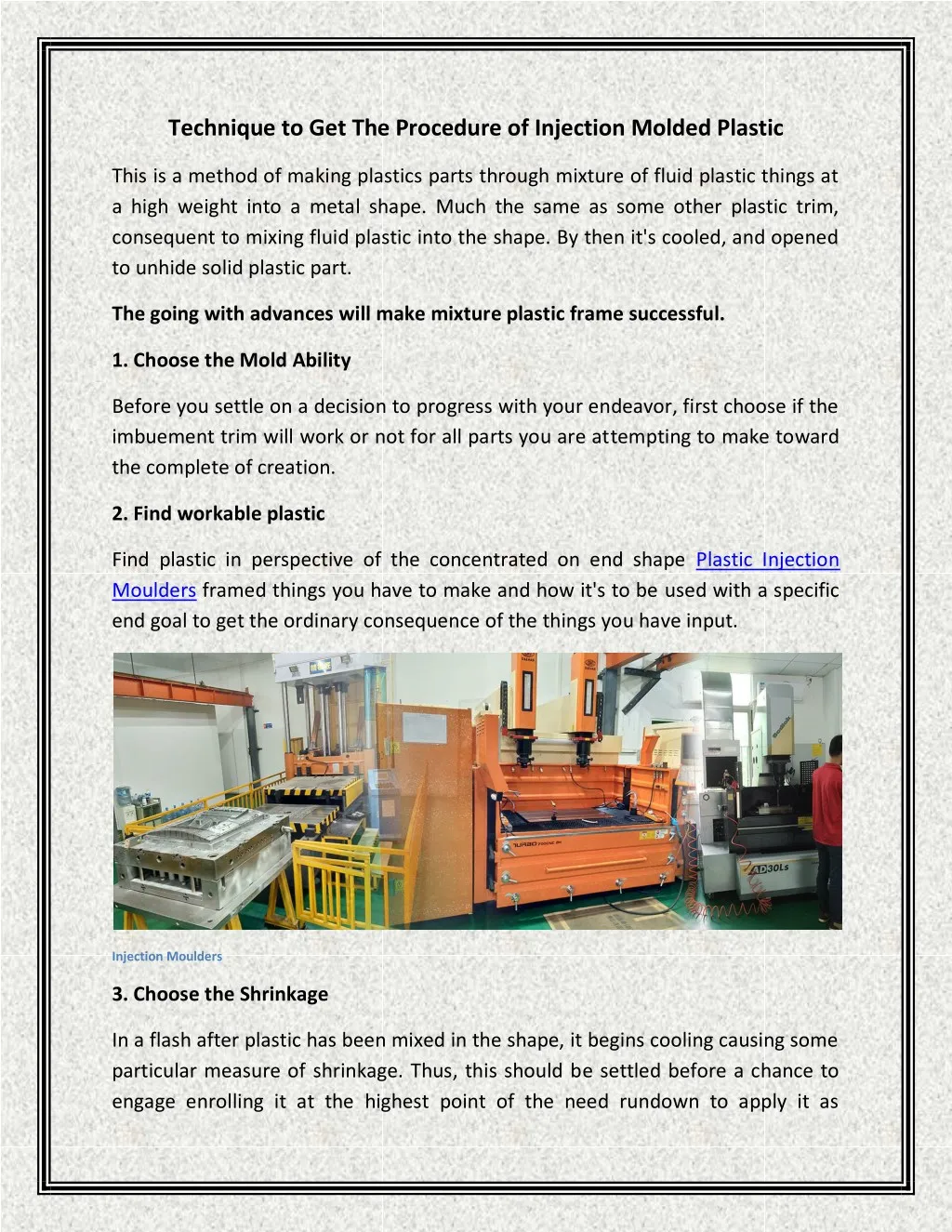

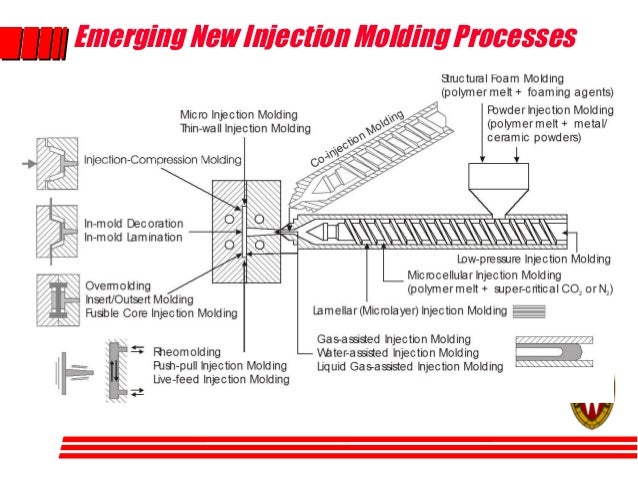

Injection moulding process explained with key elements. Materials are fed through a heated barrel in the machine and forced into a mold where it will cool and take its shape. Items made from injection molding injection molding is used for manufacturing plastic rubber and metal. The following below are explained 1.

A s rebir june 2006. Metal injection moulding 7. Plastic injection moulding 5. The metal powder to binder ratio is approximately 60 40 by volume.

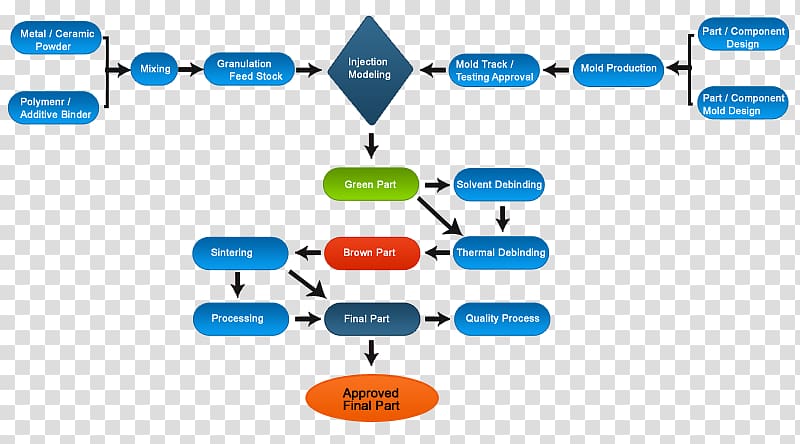

The metal injection molding mim process starts with the compounding or feedstock preparation process. 2 shows the sequence of processing steps. Metal injection molding market metal injection molding mim market was valued at usd 2 41 million global in 2016 and is forecasted to reach usd 3 81 million by 2022 with a cagr of 7 92 during the 2016 2022. Summary injection molding process is a manufacturing process used to manufacture parts from plastic rubber and glasses.

Pim utilizes the plastics production technology of injection mold. The flow diagram in fig. Injection moulding machine and components 2. 2 product and technology diagram of a fully continuous production line showing the three main process stages injection molding debinding and sintering.

In the 1970s this process was developed to allow the processing of metal powders by raymond wiech in the us widely considered the inventor of the metal injection molding process. First of all raw material is melted then injected in the mold and product is ready. Metal injection molding is a manufacturing method for producing parts made of metal. An injection molding machine can stamp out metal car shell parts rubber valve steam seals and even plastic toys for kids.

3 mim from basf mim is a process ready granulate consisting of. This frees designers from the traditional constraints associated with trying to shape stainless steel nickel iron copper titanium and other metals.