Mig Welder Wire Stuck In Liner

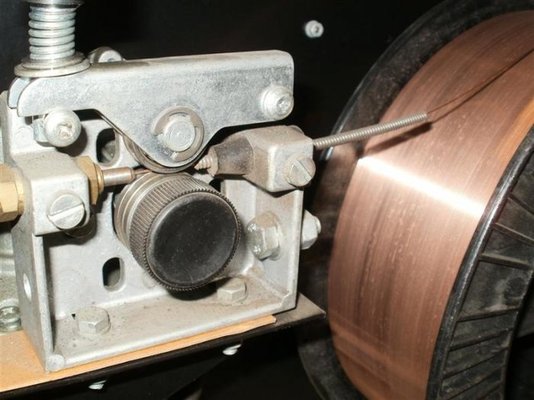

This lets the aluminum through more smoothly.

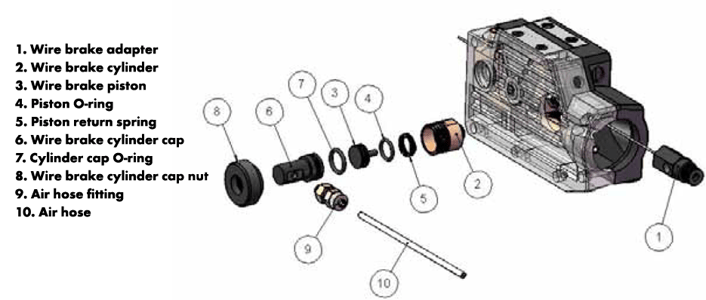

Mig welder wire stuck in liner. Next remove the old liner and then feed in the new liner. How do you change mig welder liner. If you switch off your device and the mig welder doesn t go off until you cut off the power supply it means merely your liner needs to switch out. You should then be able to remove the liner by pulling it out welder end of cable if not look for some type of set screw or fastener holding it in it could be at ether end.

The one you need is going to be determined by your mig wire. One of the most common problems with an mig welder is the welding wire becoming stuck in the welding gun. When the welding wire becomes stuck you must remove it or the welding gun can be. Aluminum wire will require teflon liners.

By switching liner and connection it helps to replace things worn and get back your job in quick time. Aluminum is soft enough to move very quickly through the line and offers less drag. Depending on what machine you have just pull the liner out of the welding gun assembly. First remove the old liner along with the welding wire nozzle tip and diffusor.

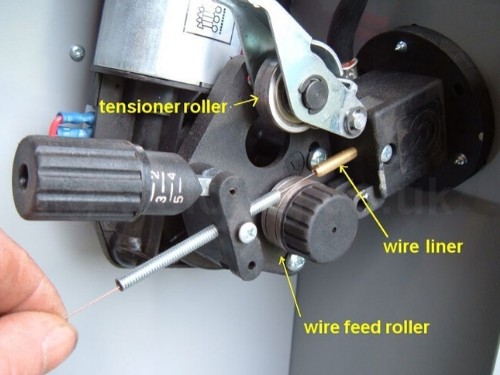

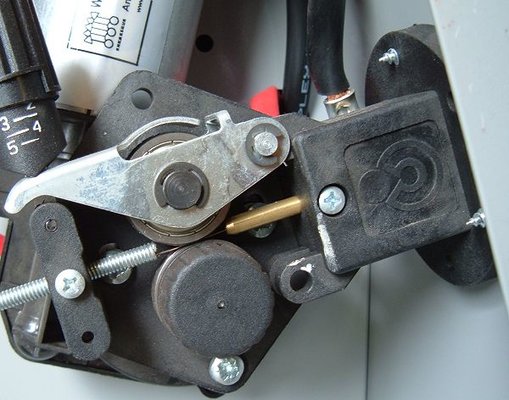

There are a couple of different liners used in mig welding machines. Through 045 in have relatively low columnar strength which when paired with an oversized liner can cause the wire to wander or drift within the liner. Once the new liner is in trim the liner to around 3 4 where it comes out of the neck of the weld gun. To maximize the performance of your mig equipment choose the correct liner size for the wire being used.

Small diameter welding wires 023 in. Remove the mig gun cable and all from the welder. Choose the right size. Finally reattach the liner back to the welder and put the.