Metal Pipe Bending Techniques

When bending a hot metal apply pressure to as small an area as possible to minimize strain on the metal.

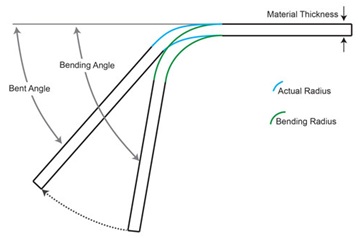

Metal pipe bending techniques. Below are some tips form pipe bending experts that will help you achieve the perfect bend. And the centerline radius or the neutral line where neither compression nor stretching occurs the bend angle refers to the complementary angle of bend. This material provides a great resistance to the unavoidable chemical process. Stainless steel tube bending.

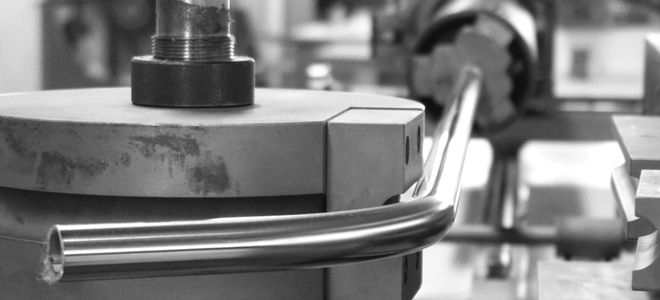

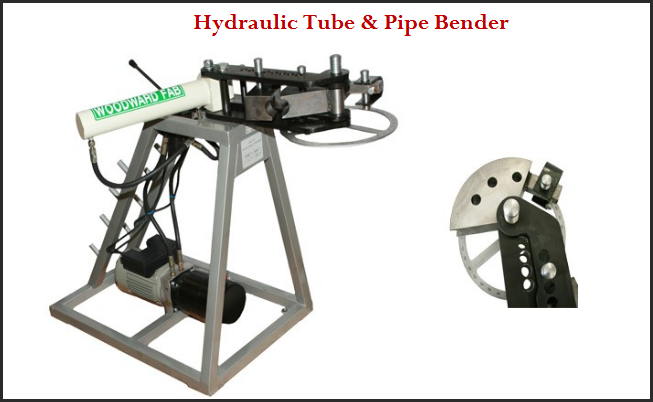

When using a hydraulic pipe bender make sure the sizes of the former and bender roller are precise for the size of the pipe. Artist kevin caron shows two ways to shape metal pipe should you roll or should you bend it. Metal fabrication requires care and precision but learning how to bend tube and pipe can give you more control over your projects. Bends often require achieving a tight radius.

Common application for our stainless steel pipe bending include cooling coils hydraulic fluid supply lines manifold assemblies and more. Each is best suited to a particular type of pipe. Once the metal has been bent let it cool slowly so the crystals have time to reorganize and stay hard. If you use a hammer try to bend the metal around a template.

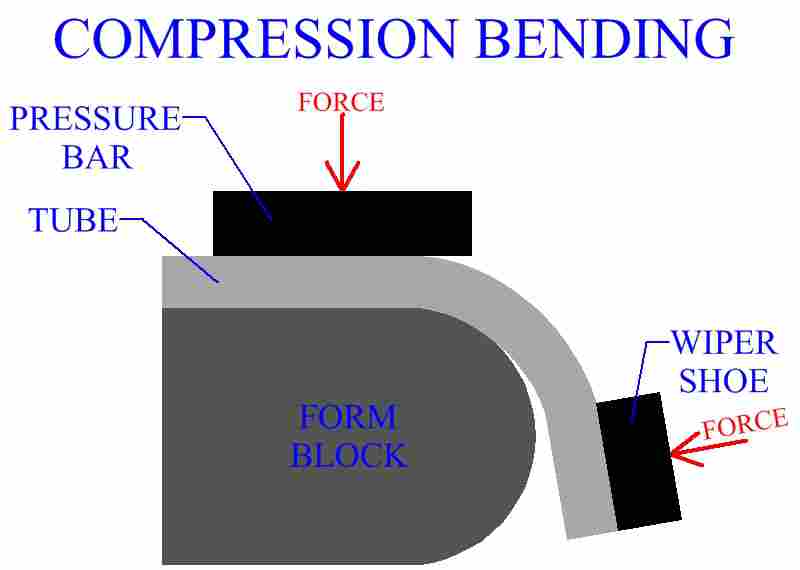

However there is some troubleshooting to do when performing steel tube bending. Tube and pipe bending can be done a number of ways with a variety of tools. On the other hand stainless steel tubes and pipes are useful in places where corrosion is imminent. The more advanced bending machines for pipe and tubing may be more cost effective in commercial or industrial applications but simpler pipe and tube benders can find a prized place in the workshop.

So if a tube is bent to 45 degrees that s 45 degrees complementary or a 135 degree included bend angle. In this article i ll go over a few different options based on what your application is as well as how you can pull this off properly. There are 6 main bending methods. Ram style bending also called incremental bending is usually used for putting large bends in light gauge metal such as electrical conduit.

Custom stainless steel tube bending is available for diameters up to 2 1 2 and common grades of metal including 301 304 316 and others. How to properly bend metal pipe and tube at home. Choose the right bending tools for your needs. Other bending variables include the inside bend radius sometimes called the intrados.

Just look for whatever best matches what you re trying to do. Hot metal is very easy to over bend.